Navigating the Risks of Glass in Buildings: A Guide to Safety

Discussion of how glass can be used in buildings to enhance safety, such as through the use of tempered or laminated glass.

Usage of glass, both interior and exterior, has grown over the past century due to its practicality and functionality. Most has attributed it to its strength, versatility, and visual aesthetics. Achieving such positive attributes does have its trade off too. One of the main safety concerns surrounding glass is the risk of breakage. Modern glass is designed to be strong and resistant to breakage, but it is still possible for it to break due to impact or other external factors.

However over the years, several measures had taken place to reduce such risks. Let us look at some of the different methods that have been adopted and applied to glass to enhanced its strength and safety usage across all its platform.

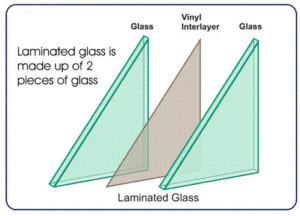

Laminated Glass

Fig 1: Laminated Glass Diagram: https://brennancorp.com/blog/tempered-glass-vs-laminated-glass-comparison-and-review/

Laminated Safety Glass is formed by two or more pieces of glass bonded together by a tough, durable interlayer under heat and pressure. When broken by impact, the glass will adhere to the interlayer and stay in the frame hence minimizing the risk of injury from sharp edges and strongly resisting penetration by the impacting objects or person. As such, it is classified as a safety glass.

Specialised interlayers available are Polyvinyl Butyral (PVB), Ethylene vinyl acetate (EVA) or SentryGlas® (SG). The standard range of PVB colours in the Vanceva colour system allows the creation of more than 1,000 different tints from a palette of 9 basic colours and 2 translucent white interlayers befitting to your design requirements.

Check out SSG® DuraSafe & SSG® DuraSafe-SGP here

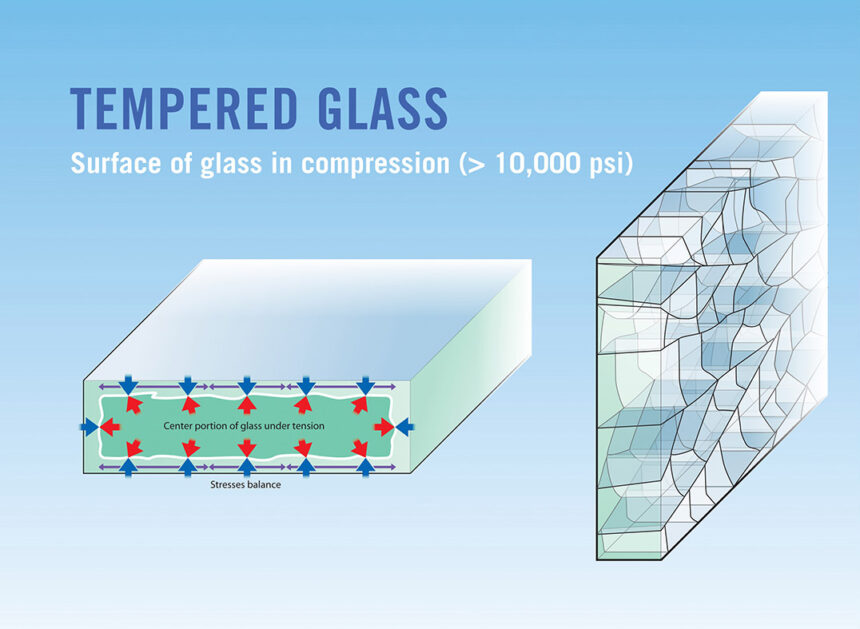

Tempered Glass

Fig 2: Tempered Glass Diagram: https://glassed.vitroglazings.com/topics/heat-strengthened-vs-tempered-glass

Tempered Glass employs the use of a thermal process to enhance the basic strength of annealed glass via a tempering furnace. Annealed glass is heated close to its softening point; it is then rapidly quenched by directing jets of cold air onto its surface. The surfaces are placed in compression during the quenching process, resulting in balanced induced stresses giving it added mechanical, thermal and impact resistance properties.

The tempering process does not alter visible light and solar radiant heat properties of the glass. Coated glass, such as low emissivity glass providing solar control with high visible light transmission can be tempered too. Spontaneous breakages due to nickel sulphide formation can also be reduced via additional heat-soaking as featured in SSG DuraGlas-Q.

SSG Protection Series

Glass can also pose a safety risk in certain situations, such as during earthquakes or high winds. In these cases, it is important to use special types of glass that are designed to withstand such conditions.

Check out our Protection Series for more glazing solutions for protection from Natural Disasters

Overall, glass is a safe material when used properly. By taking appropriate measures to reduce the risk of breakage and injury, and by using special types of glass in certain situations, it is possible to use glass safely in buildings.

We hope you have found this information helpful. If you have any questions about the various glazing solutions available, please do not hesitate to reach out to us.